Summary

NHS Wales is committed to achieving Net Zero by 2030. Partnering with GV Health, a leading provider of sustainable healthcare solutions, NHS Wales has implemented innovative measures to reduce plastic waste and carbon emissions. Key initiatives include introducing a minimum of 30% recycled content across the waste bag range, optimising raw material usage, streamlining product ranges, and improving packaging and transportation efficiency. These efforts have resulted in significant annual savings, a reduction of over 26 tonnes of plastic waste per year, and a carbon footprint reduction of 31.6 tonnes of CO2e per year. Together, NHS Wales and GV Health are driving sustainable procurement and waste management practices to create a cleaner, greener healthcare system.

NHS Wales Shared Services Partnership said,

“Overall the project has had a very positive impact on NHS Wales. The project has been easy to roll out with minimum involvement from NHS Wales due to the heavy support from GV Health.”

These collaborative projects have resulted in GV Health being shortlisted for two awards at the NHS Wales Sustainability Awards, the “Service of the Year Award” and the “Product of the Year” award.

Introduction to worldwide plastic crisis

Climate change is happening, and its impacts are visible worldwide. The Earth’s average temperature has risen by more than 1°C since the 1850s, and this warming trend is driven by human activities. Single-use plastics contribute significantly to climate change, accounting for approximately 3-4% of global greenhouse gas emissions. This contribution stems from the production, use, and disposal of plastic, with the most significant impact coming from the extraction and refining of fossil fuels used to create plastics.

Plastic pollution is also having a detrimental impact on ecosystems, wildlife, and human health. The challenge is exacerbated by the rapid increase in plastic production and consumption, coupled with inadequate waste management infrastructure across the world. Plastics production has quadrupled in the last 30 years, in 2020, more than 380 million tonnes of plastic was produced worldwide, and whilst recycling rates are improving, only 16% of plastic waste is recycled to make new plastics, 40% is sent to landfill, 25% to incineration and 19% is dumped. It is estimated that as much as 22% of all plastics escape waste management altogether and enter the environment in a completely uncontrolled way. Every day, the equivalent of 2,000 garbage trucks full of plastic are dumped into the world’s oceans, rivers, and lakes and the problem is growing year on year.

The NHS

In the UK, the NHS is not only the biggest producer of healthcare waste in Europe, but also the largest user of single use plastics, creating around 133,000 tonnes of plastic annually with only 5% of it being recyclable. Depending on its use, plastic waste is disposed across several waste streams, including landfill, incineration, recycling, or a resource for other industries. With such a small % being recycled, a huge amount of plastic is ending up in either landfill or incineration.

Plastics in landfill poses significant environmental problems because it does not decompose and instead breaks down into microplastics over time, releasing harmful toxins and greenhouse gases, causing significant implications for the climate. Burning plastic in incinerators is also causing significant problems and more waste than ever is being incinerated, not only due to a growing population, but also because the UK is facing a serious problem with running out of landfill space. Incineration can be seen as a more sustainable option compared to landfill due to generating energy from waste and prevents the release of methane, however, incinerating waste also releases harmful toxins, greenhouse gases, and pollutants into the atmosphere. Additionally, incineration is not a complete solution for plastic waste, as some plastics and microplastics may persist in the bottom ash.

The cost of clinical waste disposal can be significantly higher than non-clinical waste, reaching £503 per tonne for clinical waste compared to £160 for non-clinical. On average, the NHS currently produces an estimated 156,000 tonnes of clinical waste every year from secondary care (based on ERIC data 2020/21). The estimated carbon impact of this waste is approximately 100,000 tonnes of CO2e per year.

Single Use Plastics and the Waste Hierarchy

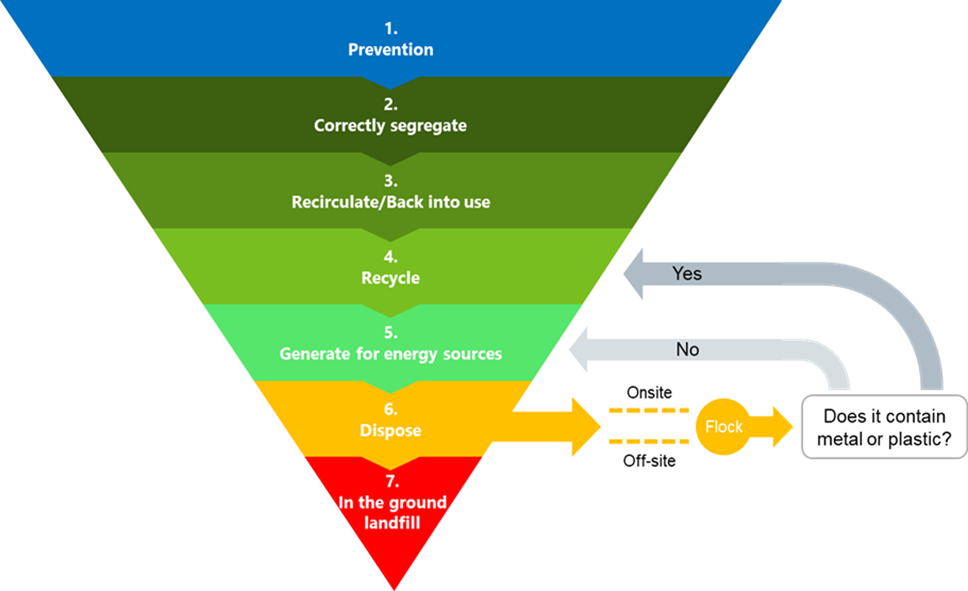

The waste hierarchy, as described by the Department for Environment, Food and Rural Affairs (Defra) is a framework that ranks waste management options according to what is best for the environment, it gives top priority to preventing waste in the first place. The waste hierarchy is especially important in the healthcare industry, where huge amounts of waste are produced every day, therefore we need to prioritise efforts to reduce waste generation in the most environmentally sustainable way.

Adopting the waste hierarchy and improving waste management, does not only help to improve sustainability, but it can also lead to significant cost savings by reducing procurement costs and waste disposal fees. It supports a circular economy, when waste is created, the hierarchy gives priority to preparing it for re-use, then recycling, then recovery, and last of all, disposal. The waste hierarchy also encouraging manufacturers and waste management companies to find innovative solutions to reduce waste and bring more sustainable solutions to the market.

Single-use plastics should ideally be moved towards the top of the waste hierarchy because they often have a short lifespan and are designed for a single use, which means they quickly become waste. Therefore, prioritising prevention and reduction over recycling and disposal is crucial for minimising their environmental impact. This means making conscious choices to minimise their use, and/or find more environmentally friendly options, such as items which are made with less plastic, or reusable alternatives if possible. With the UK healthcare industry on the route to Net Zero, it’s more important than ever to use tools such as the waste hierarchy to support the journey and achieve the target.

What is being done across the NHS

The NHS committed to reaching Net Zero in October 2020 to address the growing health threat posed by climate change. Recognising that the climate emergency is also a health emergency, the NHS aims to improve healthcare while reducing carbon emissions and investing in efforts to remove greenhouse gases from the atmosphere.

The NHS in England has a legally binding commitment to achieve Net Zero by 2040. In 2023 the NHS Clinical Waste Strategy was introduced, which is a 10-year strategy to improve NHS waste management practices and align with Net-Zero targets. With around 156,000 tonnes of clinical waste being produced each year by the NHS, which is the equivalent to over 400 loaded jumbo jets of waste, the strategy aims to reduce waste volumes, lower carbon emissions, and save money while ensuring responsible environmental management of clinical waste. It focuses on key areas like data, workforce, compliance, commercial aspects, infrastructure, and sustainability.

The strategy states the best waste management practices reduce waste, improve compliance, and can lead to significant cost savings from lower waste volumes. It encourages the use of innovation to increase NHS waste management resilience, improved data use to help guide decision making, and improved staff engagement and training to improve compliance and seek out carbon reduction opportunities in the system.

The strategy estimates that the NHS will be able to save approximately £11 million every year in recurrent revenue costs, and it will reduce carbon emissions from waste by approximately 30% – equivalent to removing 2 million road miles a year!

Below is a chronological timeline of the NHS Clinical Waste Strategy showing the measures of success and the target dates from 2023 to 2030. With two very big targets set for 2026, it is imperative that effective waste management is implemented to ensure waste is being disposed of in a safe, cost efficient and sustainable way.

Correct waste segregation for clinical waste in line with the NHS Clinical Waste Strategy targets, 20:20:60 – 20% for high-temperature incineration, 20% for alternative treatment, and 60% for offensive waste, will ultimately leading to less waste needing high temperature incineration and more sustainable waste management practices. This will support in reducing carbon emissions, cost savings, and improved environmental sustainability, as well as contributing to better health and safety for staff and patients by minimising the risks associated with improper waste disposal.

NHS Wales

The Welsh Government declared a Climate Emergency and committed to achieving Net Zero by 2030. In 2018/19 the total NHS Wales Carbon Footprint was approximately 1 million tonnes of CO2e which represents around 2.6% of Wales’s total greenhouse gas emissions. To stimulate engagement and put in place action plans across Wales to achieve their Net Zero goal, the NHS Wales Decarbonisation Strategic Delivery Plan was introduced in 2021.

In this plan NHS Wales recognises decarbonisation of NHS Wales is split into six main activity streams: Carbon Management, Buildings, Transport, Procurement, Estate Planning and Land Use and Approach to Healthcare. In 2018/2019 procurement made up 62% of their total Carbon Footprint, accounting for 623,750 t CO2e. The plan aims to embed NHS Wales’s decarbonisation ambitions in procurement procedures by mandating suppliers to decarbonise and actively develop and support procurement requirements to support implementation of the Delivery Plan. It also aims to improve all supply chain logistics and distribution to reduce the carbon emissions from associated transport.

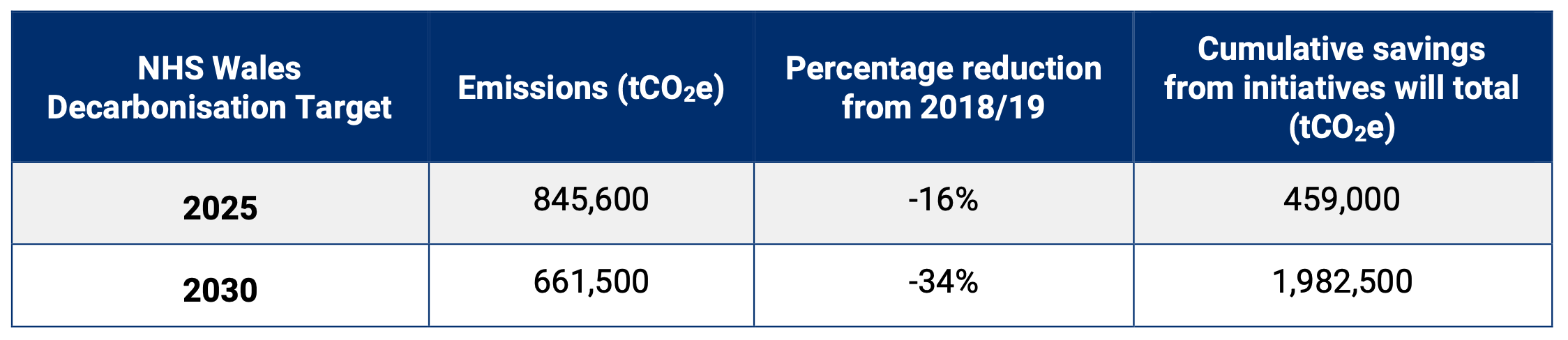

In order to reach Net Zero by 2030, NHS Wales set the below decarbonisation targets for 2025 and 2030:

Introduction to GV Health

GV Health Ltd is a Science and Technology company at the forefront of infection prevention and control and waste management in healthcare. We have been a contracted provider to the NHS for over 30 years of products, services and innovation, and our mission is to create safer environments for human health through science and innovation to drive better outcomes in healthcare infection prevention and control and waste management.

Being one of the largest manufacturers and suppliers of polythene single use clinical and domestic waste bags and aprons for the NHS, we acknowledge our products significantly contribute to single-use plastic consumption within the NHS.

We have invested heavily in our Technical Team of highly qualified experts, including sustainability scientists, and our new state of the art laboratory, home to our groundbreaking innovations. Having a team of dedicated scientists for chemistry, polymer and sustainability means we are actively engaged in researching advancements that encourage innovation, allowing us to stay at the forefront of the industry, whilst ensuring that our products consistently set new benchmarks for sustainability, efficacy and maintain high performance. Given the nature of our products, with the majority being clinical waste bags, it is imperative that we adhere to the stringent industry regulations whilst focusing on making our products more sustainable to ensure a clean and safe environment and help prevent the spread of infection.

How GV Health have supported NHS Wales on their road to Net Zero

Our direct contract with NHS Wales started in October 2021 when we were awarded the contract for manufacturing and supplying clinical and domestic waste bags and aprons. With NHS Wales’s ambitious Net Zero target and 62% of their Carbon Footprint coming from Procurement, we recognised supporting sustainable procurement is an effective way to help reduce their carbon footprint.

Being experts in manufacturing polymer waste bags and aprons, we recognised that the clinical and domestic bag range for NHS Wales had not been innovated for some time. Therefore, our Technical Team of experts recommended that we complete several large-scale projects to make the Framework more sustainable and forward thinking. Focusing on innovation throughout the life cycle of each product, which entails looking at the % of recycled content and the amount of raw material used during manufacture, packaging, and transportation and storage to ensure our supply chain is operating as efficiently and sustainably as possible.

The projects have been completed in partnership with NHS Wales have achieved an annual reduction in carbon footprint by 31.6 tonnes of CO2e, the estimated equivalent is 1,470 mature trees absorb this much CO2e in a year.

More information on these projects below:

1. Introducing Recycled Content

The Plastic Packaging Tax (PPT) was introduced in 2022, which is a UK tax on finished plastic packaging components that contain less than 30% recycled plastic. The tax aims to encourage businesses to use more recycled plastic in their packaging and products, thereby stimulating recycling and collection of plastic waste, leading to significant carbon savings and diverting plastic from landfill and incineration.

Introducing recycled content into a polythene bag is challenging, especially for clinical waste bags, given the stringent safety standard, as the strength, performance and consistency of products containing recycled content varies considerably compared to products made of virgin material. At GV Health our factories operate a closed loop supply chain, ensuring our products are manufactured with a high-quality grade of recycled content. Adjusting the % of polythene used (LDPE, HDPE, LLPDE) in each product whilst increasing the % of recycled content is extremely challenging and a lengthy research and development process to ensure consistency and performance, which is imperative when manufacturing any waste bag, but particularly clinical waste bags.

With the NHS Wales bag range being predominately clinical waste bags, quality and performance is crucial, and understanding the rigorous testing required to obtain the relevant UN certification. Our Technical Team invested significantly in this area, enabling us to be the first UK bag manufacturer to achieve 30% recycled content in 100% of our clinical waste bags; and now the entire range of clinical and domestic waste bags supplied into NHS Wales is manufactured using a minimum of 30% recycled content. This adheres to the Plastic Packaging Tax introduced in 2022, contributing to a cleaner environment by operating a closed loop supply chain and using more recycled content over virgin material. This enables less plastic entering the waste stream, supporting sustainable procurement and a reduction in carbon footprint as less plastic is being sent to landfill or incineration.

2. Reducing raw material

To further reduce plastic waste across NHS Wales, we recognised the bags were over the necessary specification for their use, and being manufactured using more raw material than needed to meet the required testing. An example is the yellow mattress bag, where the Framework for NHS Wales stated it had to be 125 microns, this is relating to the thickness requirement of the bag. At GV Health, we have manufactured and supplied yellow mattress bags into the NHS for decades, and after a huge amount of research, development, testing and trialling, we supply the same product, yellow mattress bags, at 75 microns in bulk across the NHS in England. Therefore, we have now successfully made this change across the whole of NHS Wales, consequently reducing the volume of plastic used when manufacturing and disposing each mattress bag across NHS Wales.

Using our Technical Teams expertise along with our new manufacturing technology, in total we reduced the amount of raw material across 13 products out of the 25 on the Framework. We worked with several Health Boards on this project completing a number of trials to ensure the products achieved the same strength, performance and quality with less raw material.

NHS Wales Shared Services Partnership said,

“The projects have helped reduce our overall plastic consumption.”

The results have achieved an estimated annual reduction in carbon footprint of 27.8 tonnes of CO2e and an annual reduction in plastic weight of 24.7 tonnes. This is a significant reduction in plastic being sent to landfill or incineration, reducing carbon emissions, air pollution, as well as reducing costs to dispose of this volume of plastic in the relevant waste stream.

3. Packaging, Transportation and Storage

At GV Health, we also recognise and explore opportunities to reduce CO2 emissions on factors outside of the product itself. Supplying and transporting the largest volume of bags and aprons per box and per pallet, in line with health and safety regulations, can have a significant impact on transportation, storage and packaging carbon footprint. A project we completed with NHS Wales, enabled us to increase the box size of 7 product lines, which achieved an annual reduction in total mass of the goods by over 26 tonnes, equivalent to over 200,000 plastic water bottles, with each 1 litre PET bottle emitting approximately 130 CO2e through production and transport. Also, a 19.5% reduction and the total volume was lower by 67.8m3, a 23% reduction in storage related Carbon Footprint.

NHS Wales Shared Services Partnership said,

“Reducing the number of products on the Framework has reduced our storage”.

We have also removed all plastic packaging across our aprons replacing them with paper sleeves, leading to an annual reduction of 298kg of plastic, equivalent to a further 2,300 plastic water bottles, and an annual reduction in overall packaging by 99.5kg per year. Again, contributing to less plastic needing to be incinerated or sent to landfill reducing costs and creating a cleaner environment.

4. Supporting the Welsh Economy

At the start of the contract, we also invested in a brand-new Warehouse in Wales, recognising the importance of social value, sustainable procurement and supply chains emissions. Therefore, we strategically chose and opened a Warehouse in Wales to service this contract which is close to the Newport and Bridgend Stores. This has enabled a reduction in annual milage to NHS Wales Stores by over 25,000 miles per year. Achieving a significant reduction in Carbon Footprint compared to servicing the contract from our main Warehouse. The new Warehouse in Wales has also supported the Welsh economy, by providing in a number of new jobs in the Warehouse and across our logistics.

5. Streamlining and Consolidation

We also recognise that streamlining the product range and operating as efficiently as possible will further reduce CO2emissions in manufacturing, transportation and storage. We identified several opportunities for consolidation across the NHS Wales product range where there were very similar product specifications and consequently products with low demand. These opportunities were across clinical and domestic waste bags, for example we have managed to reduce the orange clinical waste bags from 4 lines to 3, and we have managed to reduce the clear bags from 9 bag lines to 5 bags. Overall, we have managed to consolidate the range from 37 products to 25 products.

NHS Wales Shared Services Partnership said,

“Streamlining the products has meant a considerable cash release saving and has helped drive efficiency within NHS Wales.”

We worked with the Health Boards to understand the requirements and use of each bag and supported on moving the demand onto suitable higher demand product lines. For example, we noticed a low volume line was used by only one Health Board, therefore we worked with them in understanding the bag requirement and supported in supplying some alternative bags to trial. We found a suitable alternative which was a smaller bag, but able to perform to the same strength. The Health Board successfully switched to the alternative bag, creating a reduction in the amount of plastic being used per bag, and it was also a more cost-effective alternative. Across the various consolidation projects completed, we managed to reduce the volume of plastic being used in our product range by an estimated 1.6 tonnes per year and reduce our carbon footprint by 3.4 tonnes per year.

6. Overall benefits

The overall benefits of these large-scale projects have been significant in supporting NHS Wales on their journey to Net Zero by 2030.

- Achieved significant annual saving through polymer blend optimisation and consolidation

- Reduced carbon footprint by 31.6 tonnes of CO2e per year, estimated equivalent to 1,470 mature trees to absorb this much CO2e in a year.

- Reduced the volume of plastic used in manufacturing by over 26 tonnes per year, equivalent to over 200,000 plastic water bottles, with each 1 litre PET bottle emitting approximately 130g CO2e through production and transport.

- Reduced plastic apron packaging by 300kg per year, equivalent to a further 2,300 plastic water bottles.

- Reduced the total mass of products by 19.5% which is over 26 tonnes

- Reduced the total volume of products by 67.8m3, providing estimated 23% reduction in storage related Carbon Footprint

- Achieved 100% of the product range manufactured using a minimum of 30% recycled content

- Rationalised the product range from 37 products to 25

If you would like more information or support on sustainable procurement and effective waste management, contact us for more information.

Our Carbon Footprint calculations are based on UK government factors: https://www.gov.uk/government/publications/greenhouse-gas-reporting-conversion-factors-2024

References:

https://www.england.nhs.uk/estates/nhs-clinical-waste-strategy/

https://www.gov.wales/nhs-wales-decarbonisation-strategic-delivery-plan

https://www.gov.uk/government/organisations/department-for-environment-food-rural-affairs